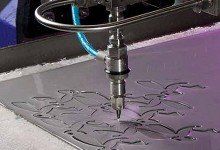

Water Jet Cutting Work

In Business Since 1938 | Family Owned | Competitive Pricing

In Business Since 1938

Family Owned

Competitive Pricing

Count on Us for Your Water Jet Cutting Needs

Marion Engineering & Technology Inc's 5-Axis water jet cutting services include cutting sizes up to 144 in. long x 72 in. wide, with thickness up to 6 in. , while holding tolerances to +/-0.003 in.

Our water jet can cut a large variety of materials such as mild steel, stainless steel, aluminum, glass, copper, brass, marble, titanium, bronze and many others.

We can work off of your cad drawings or we can create the cad drawings required to make your parts off of hand sketches or paper templates. Water jet cutting is perfect for just about anything like intricate machine parts, gaskets, brackets, decorative parts and signage just to name a few.

Advantages to Water Jet Cutting

- Fast, economical machining of virtually all metallic and non-metallic materials with near-limitless possibilities for cutting complex shapes and dimensions

- Cuts without heat - unlike cutting with flame, plasma, laser or stamping which produces heat-affected zones and fatigue zones

- There is no thermal distortion or degradation of materials

- Physical and chemical characteristics of materials cut are unaffected

- Superior edge quality, even on laminates and composites, without delamination

- Usually, no additional machining or secondary finishing required

- Minimal fixture and tooling setup reduces labor and costs

- Tight nesting of shapes reduces scrap and costs

Share On: